Description

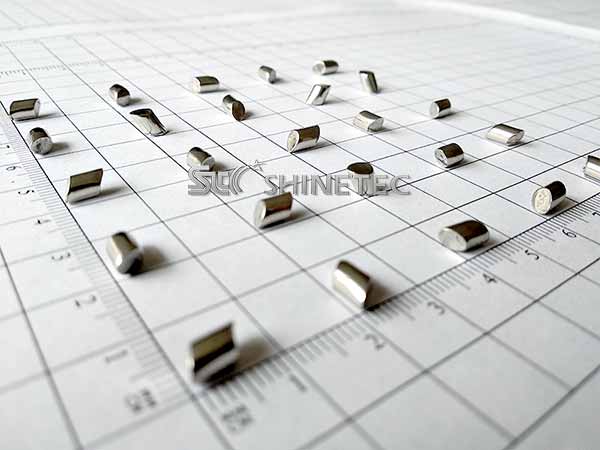

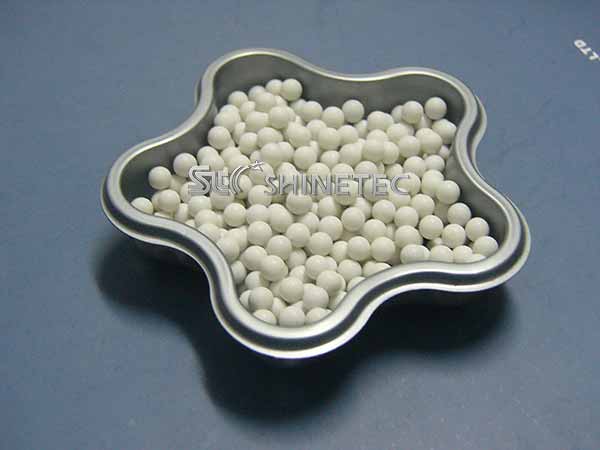

High quality stainless steel angle cut cylinder abrasive media for surface polishing, brightening and burnishing

Stainless steel angle cut cylinder polishing abrasive media are mainly used in vibratory bowl, centrifugal disc, centrifugal barrel, and tumbling polishing and mass finishing industries.

Stainless steel sphere ball polishing abrasive media are made of stainless steel wire made of 304, 316, 316L, 420, 440C and other materials through cold heading (forging), ring removal, heat treatment, rough finishing, fine finishing and other processes. The shape of the angle cut cylinder has both a beveled cape and an arc-shaped surface on the cylinder itself, which can fit the surface of the special-shaped workpiece for smooth polishing. The beveled cape can also fully touch the corners, gaps, and concavities of the workpiece. Parts such as pits that are not easily accessible to general abrasive media are ground and polished together with the workpiece in the machine.

Stainless steel media have a larger specific density. During the polishing process, they can impact the workpiece surface to produce a thicker dense layer, improve the hardness of the workpiece surface, and produce a more significant polishing effect than other polishing media. Therefore, they are mainly used for steel, iron, aluminum alloy, zinc alloy, lead-tin alloy, magnesium alloy, copper alloy and other metal product surface finishing and polishing. It can greatly improve the brightness of the product surface, and can meet the polishing and finishing needs of products in the following industries: deburring, deflashing, descaling, chamfering, etc.:

Mechanical accessories, auto parts, 3C digital, metal casting, electronic devices, medical equipment, hardware parts, kitchen supplies, aerospace, 3D printing, textile workpieces, powder metallurgy, electrical components, minting, jewelry, instrumentation, handicrafts Decoration and other industries.

Our products have excellent properties such as anti-rust and high wear resistance, long self-sharpening time, small roughness of the abrasive itself, and high smoothness. Compared with similar products on the market, the brightening effect is more outstanding, and we can provide customers with the best High quality product with great value for money.