Description

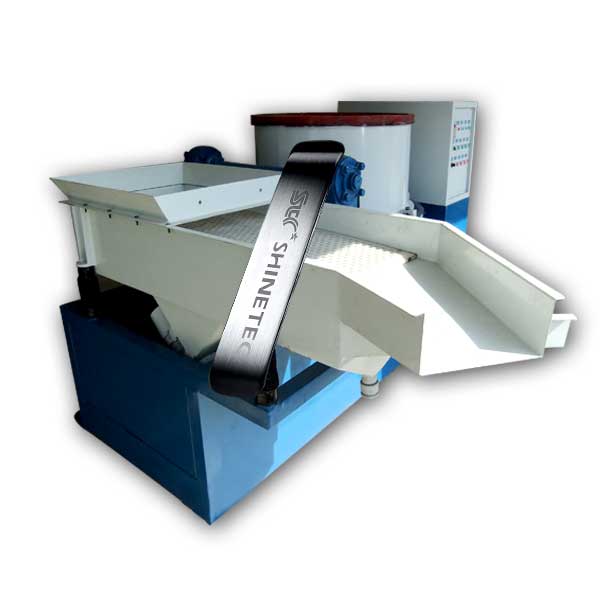

Universal Centrifugal Disc Finishing Machine

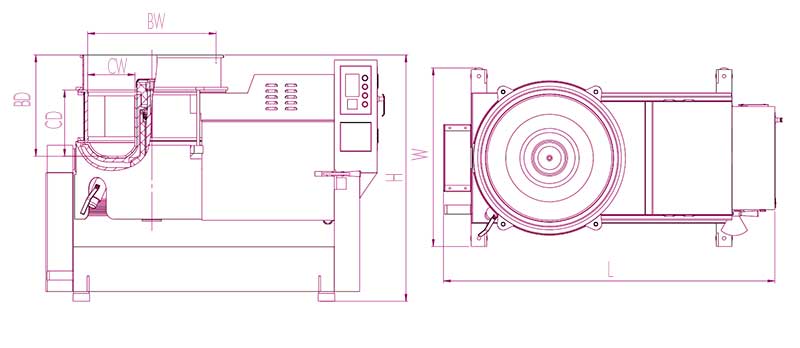

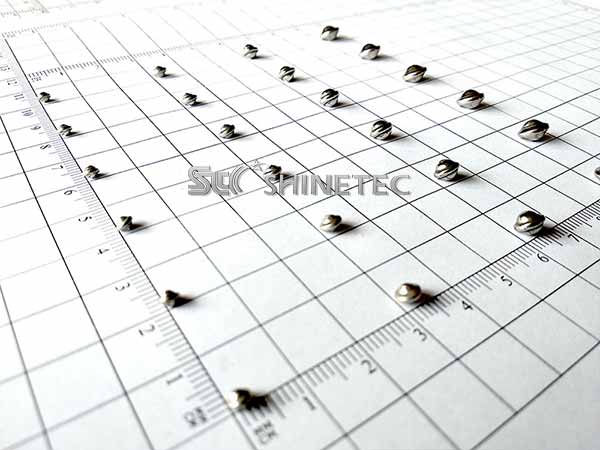

The centrifugal disc finishing machine uses an aluminum alloy rotating disk at the bottom of the machine to drive a working barrel. The centrifugal force generated during the high-speed rotation of the rotating disk and the barrel causes the workpiece and the tumbling media to rub against each other strongly, forming a spinning movement to achieve finishing and polishing effects such as deburring, deflashing, descaling, chamfering, removing the mold line, turning tool mark, and improvement of surface brightness.

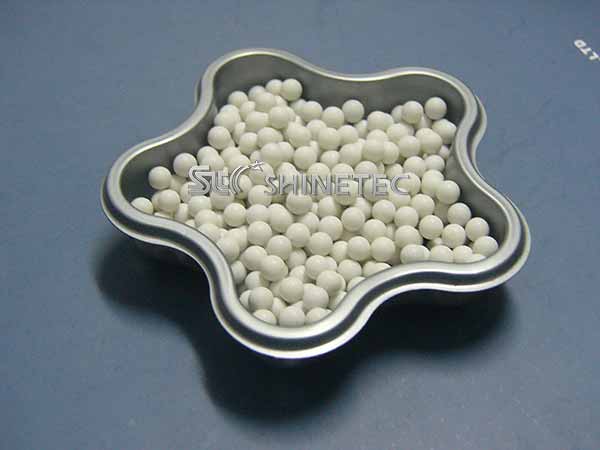

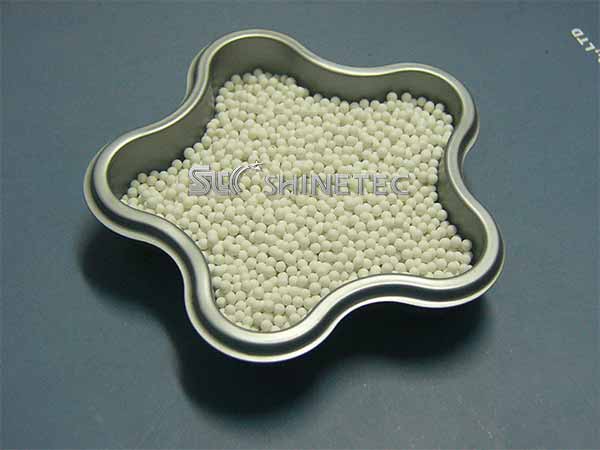

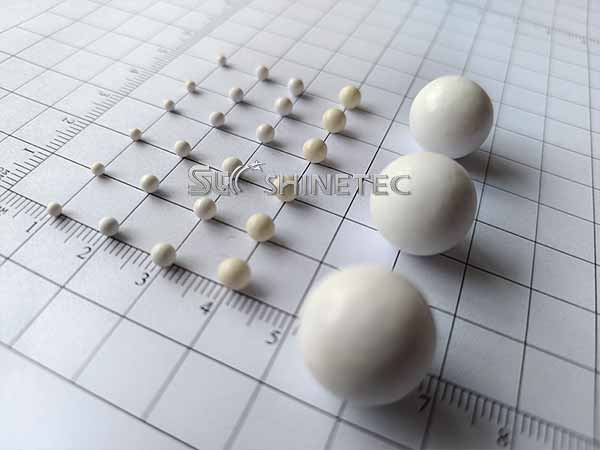

Compared with vibratory bowl finishing machines , centrifugal barrel finishing machines and barrel tumbling finishing machines , the disc finishing machine is characterized by its processing speed that is many times higher than other machines, but the noise it produces is much smaller. Short processing time, strong cutting force, and convenient loading and unloading are the main advantages of this model. However, precisely because the machine operates at a high speed and has strong finishing power, the abrasive tumbling media wear is much higher than that of other models, requiring the media to be used with stronger wear resistance.

The inside of the working barrel is a polygonal barrel hot-casted with wear-resistant polyurethane (PU). The ribbed barrel makes it easier for the tumbling media and the workpiece to tumble and collide during the finishing process during high-speed rotation. In order to achieve the purpose of improving work efficiency.

There is an integrated water catchment tray welded with steel plates under the base. After processing is completed, the sewage in the finishing barrel can be put into the water catchment tray, and then the sewage can be discharged through the drain port at the bottom of the water catchment tray.

The finishing barrel can be flipped up and down to facilitate the loading and unloading process.

This machine is suitable for finishing and polishing processing of large batches of small and medium-sized workpieces. It is not suitable for sheet-shaped workpieces that are easily deformed and have a thickness less than 1mm.

Compared with the general-purpose disc finishing machine, the drive motor of this model is located at the bottom of the finishing barrel, which can reduce the overall size of the machine and is suitable for some work areas with smaller installation space requirements.

Optional:

1. Independent control box to prevent motor current overload and cooperate with auxiliary equipment to control automatic operation.

2. Integrated devices with automatic lifting, turning, discharging and automatic feeding functions can be configured according to customer needs.

3. Optional automatic separating device for abrasives media and workpieces.