Description

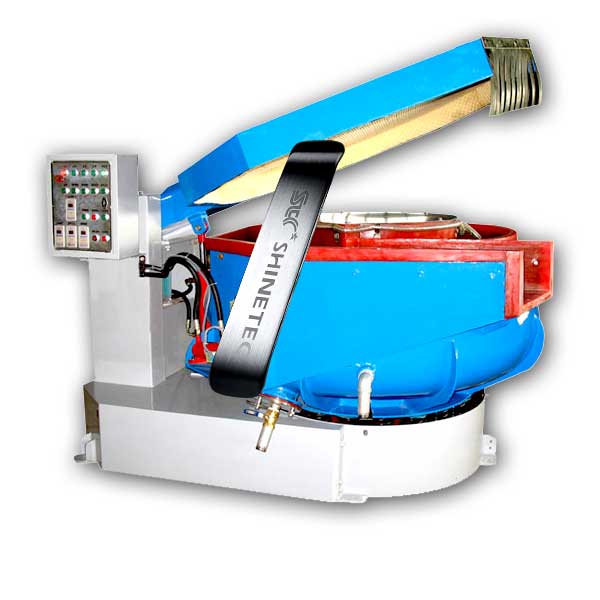

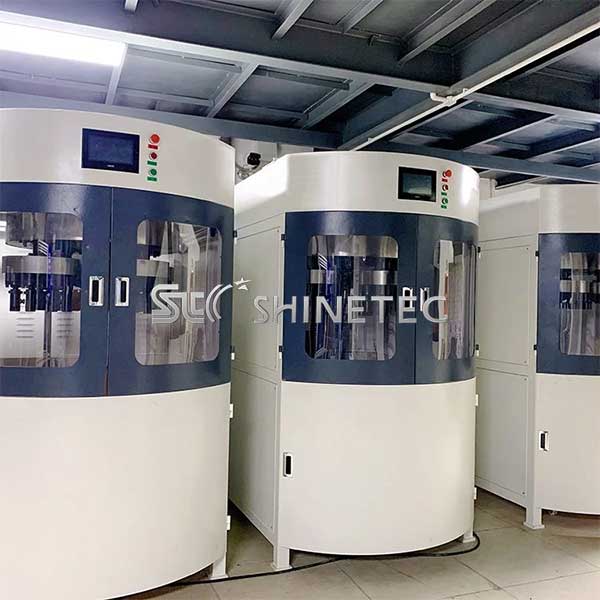

U-shaped Vibratory Bowl Finishing Machine with Separator

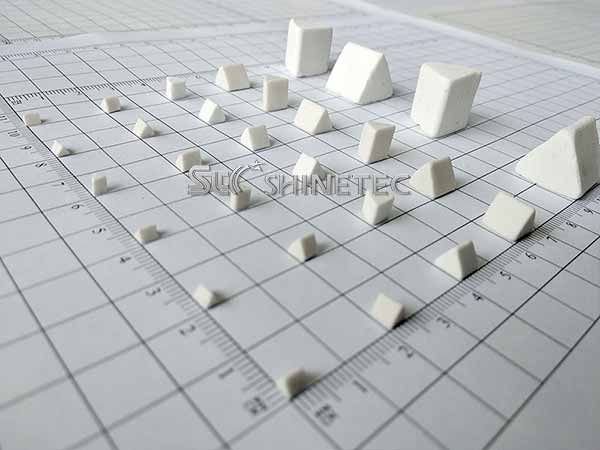

Vibratory finishing machines (also known as vibratory finisher, vibrating finishing machine), as the name suggests, uses the excitation force generated by the vibration motor to drive the tumbling media and workpiece in the working chamber of the machine to produce a reciprocating three-dimensional spiral tumbling motion, so that the workpiece and the tumbling media rub and grind with each other to remove burrs, oxide scale, and oil stains on the surface of the workpiece and improve the surface brightness.

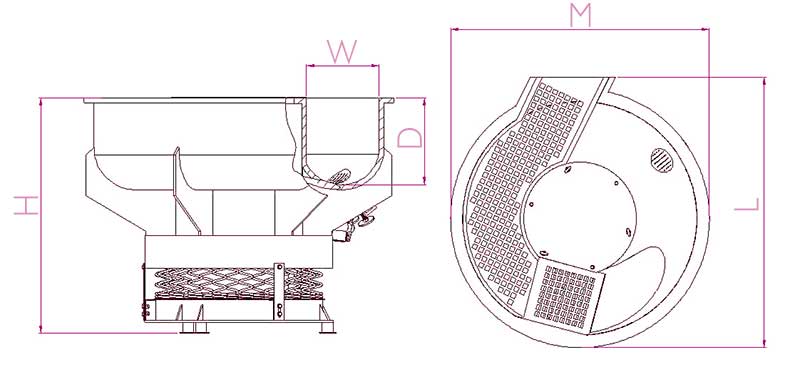

The inner wall of the working chamber of the U-shaped finishing and polishing machine is designed similar to the letter “U”. The inner wall of the upper opening of the chamber is straight. The difference from the arc-shaped finishing machine is that the width of the chamber opening is the same up and down, with the same body size, the working chamber width of the U-shaped finishing machine is larger than that of the arc-shaped finishing machine, and the outer dimensions of the workpieces processed can also be larger accordingly. In addition, it is easier to operate when picking up parts manually.

The difference between this model and the U-shaped vibratory finishing machine without separator is that this machine has an internal device for automatically screening tumbling media and workpieces. After the finishing task is completed, the workpieces can be automatically screened and output from the separating port. There is no need to manually grab each piece from the machine, which greatly improves the separation efficiency of workpieces and tumbling media after batch finishing and polishing and reduces work intensity.

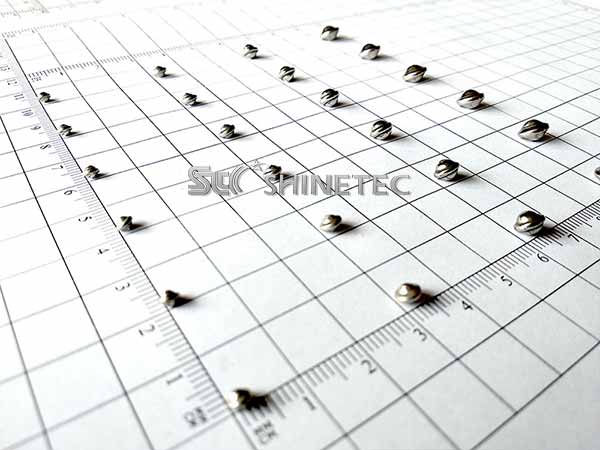

It is suitable for deburring, descaling, deflashing, degreasing, cleaning, chamfering, finishing and polishing of various workpieces of metal and non-metal products. It is especially suitable for surface finishing of complex parts with special-shaped cavities. Due to its open working chamber design, it is suitable for automatic polishing of large quantities of small and medium-sized parts. It has strong versatility and simple operation, which can greatly improve work efficiency.

The finishing and polishing process does not destroy the original size and shape of the workpiece. In addition, during the work process, the processing effect of parts can be randomly checked at any time.

Since the machine requires an integrated screening device, the minimum capacity of the machine is 100 liters, and the weight and size of the workpieces that can be processed are smaller than those without a screening separator, too large, heavy workpiece will crush the separator at discharge port.

Because the workpiece moves together with a large number of tumbling media, this machine is not suitable for workpieces that are too thin and require prevention of deformation.

Optional:

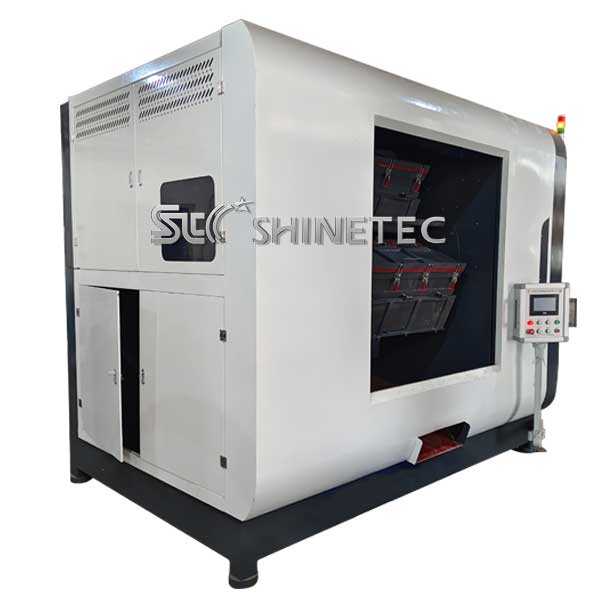

1. Sound Hood(Acoustic Lid): It can reduce noise and prevent foam splashing caused by polishing fluid.

2. Control box: facilitates safe operation of the equipment and protects the motor from current overload.

3. Frequency converter: It can adjust the vibration frequency of the machine to achieve the effect of adjusting the operating speed and vibration intensity.

4. Water&Liquid filling device: It can realize the automatic filling of polishing liquid and appropriate amount of water according to the meter during the operation of the equipment.