Description

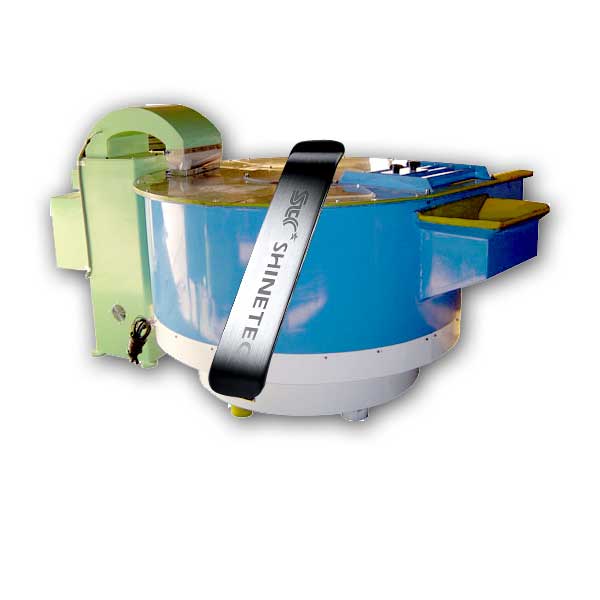

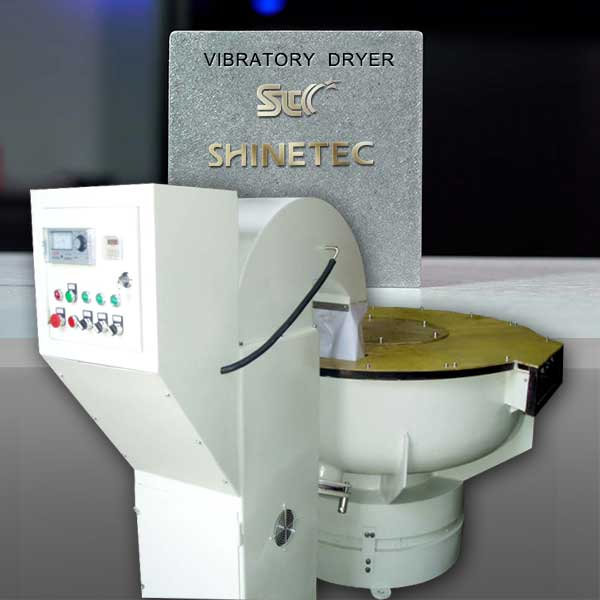

Vibratory Dryer

Vibratory dryers, also called vibrating dryers, operate on the same principle as vibrating finishing machines . The vibration motor generates excitation force, which drives the drying media and workpiece in the working tank to produce spiral three-dimensional motion. The media and the workpieces rub against each other, thereby achieving the effect of dehydration and drying of the workpieces.

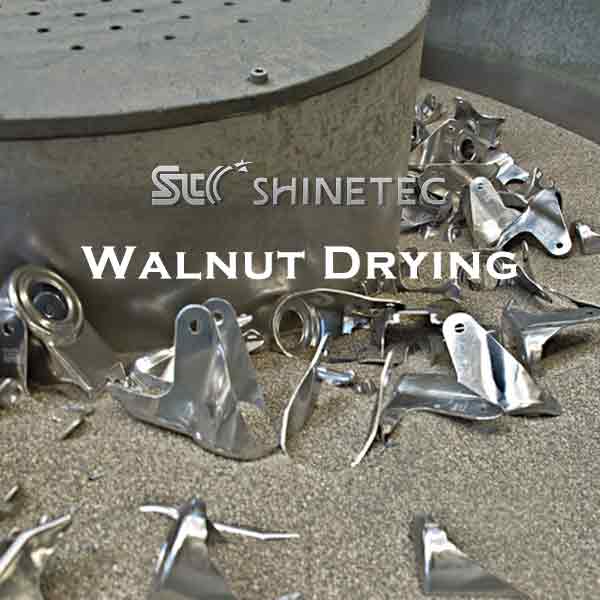

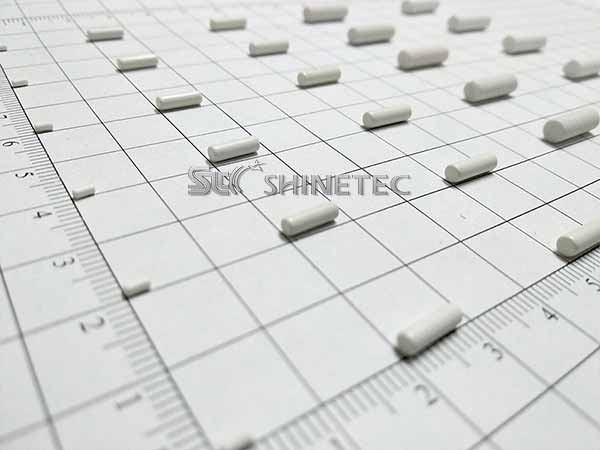

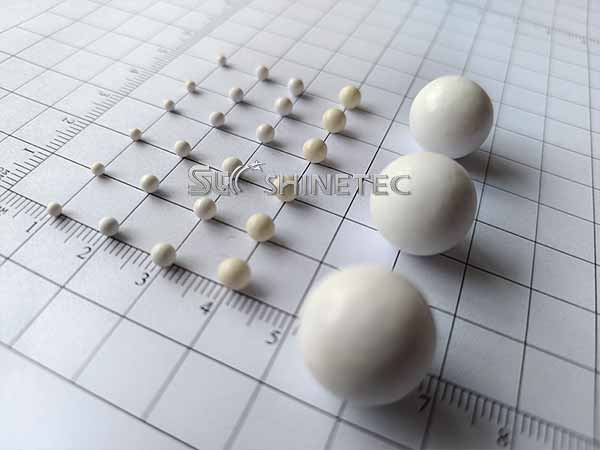

The drying media is generally composed of special corn cobs media or walnut shells media. This material is easy to absorb moisture. During operation, an electric heating tube is installed at the bottom of the working tank, which can heat the medium and speed up the drying process of the workpiece.

This drying media also has slight cutting force. During the drying process, it can also remove stains or watermarks left on the workpiece in the previous finishing and polishing process, improving the surface quality of the finished product.

It can be used as the final process of the polishing automatic assembly line and integrated into the large-volume finishing and polishing system.

Optional:

1. An independent control box can be configured to add more functional expansions, such as automatic temperature control, timing control, current overload protection, centrifugal barrel rotation speed, etc.

2. Can be configured with hot air and dust removal devices.

3. Optional rubber lining to increase temperatures during processing.

4. Pneumatic flap at the workpiece separating outlet.