Description

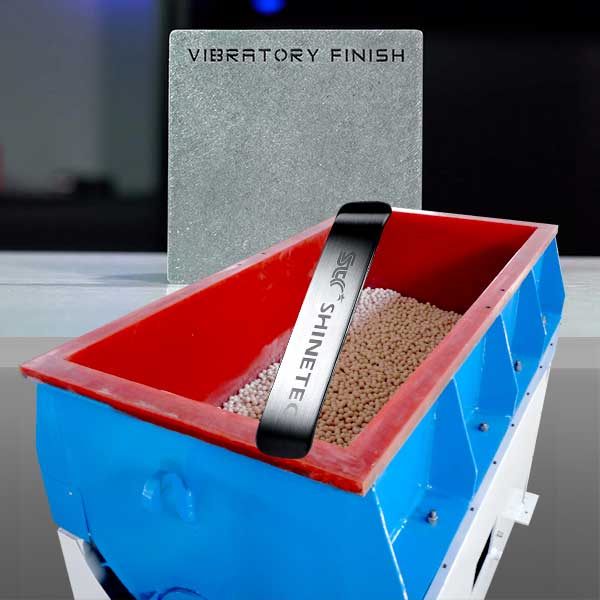

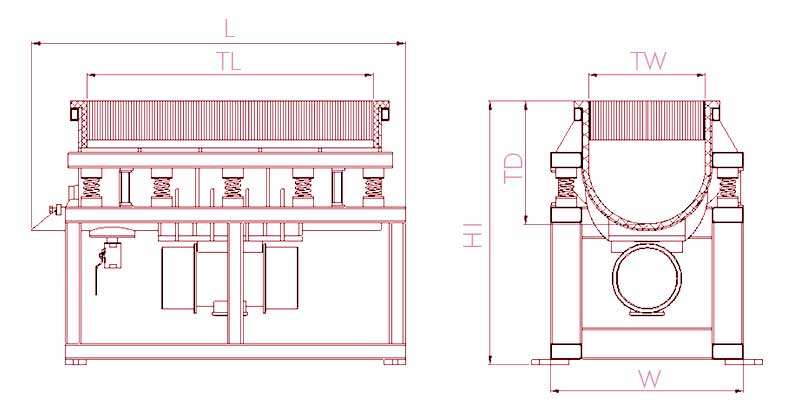

Rectangular Tub Finishing Machine

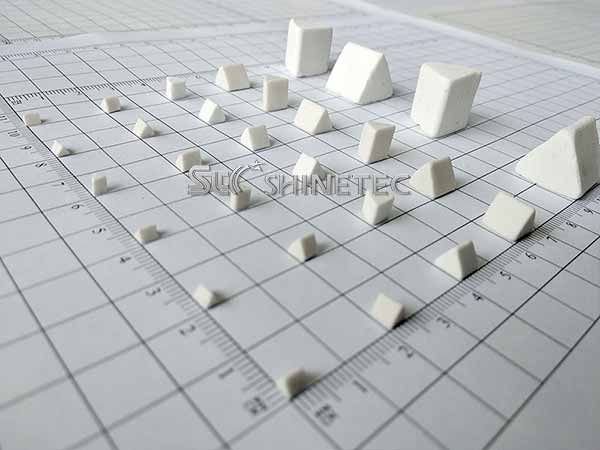

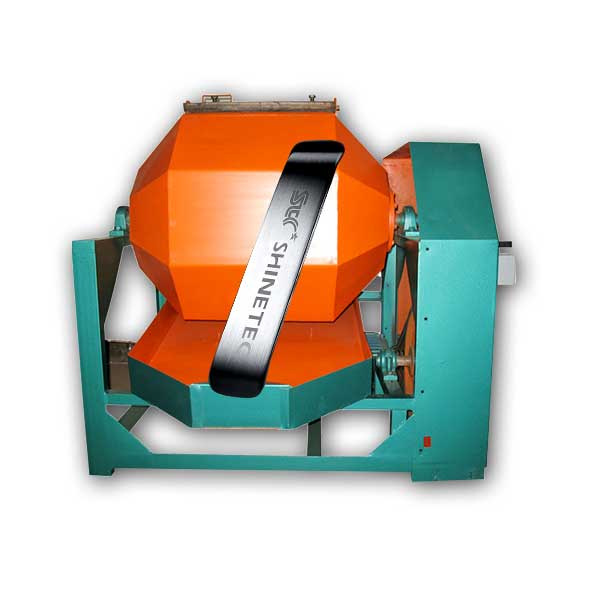

Vibratory finishing machines (also known as vibratory finisher), as the name suggests, uses the excitation force generated by the vibration motor to drive the finishing abrasive media and workpiece in the working chamber of the machine to produce a reciprocating three-dimensional spiral tumbling motion, so that the workpiece and the tumbling media rub and grind with each other to remove burrs, oxide scale, and oil stains on the surface of the workpiece and improve the surface brightness.

The rectangular tub vibratory finishing and polishing machine is the perfect choice for surface finishing of large or extra-long parts. It is suitable for deburring, descaling, degreasing, chamfering and polishing of various workpieces, both metal and non-metallic products.

The tub finisher uses the vibration deviation generated by the vibration motor to cause the workpiece and the ceramic tumbling media to produce a two-dimensional movement trajectory, so that the workpiece and the abrasive media each other in the working groove to achieve the surface finishing effect. Compared with arc-shaped or U-shaped vibrating finishing machines , the efficiency of this model is correspondingly smaller, but some long workpieces must be processed by this model. For workpieces with dimensions exceeding 500mm, it is generally recommended to use a rectangular vibratory tub machine for surface polishing.

Since the workpiece moves together with a large number of tumbling media , this machine is not suitable for workpieces that are too thin or too thin and require prevention of deformation.

Optional:

1. Sound Hood(Acoustic Lid): It can reduce noise and prevent foam splashing caused by polishing fluid.

2. Control box: facilitates safe operation of the equipment and protects the motor from current overload.

3. Frequency converter: It can adjust the vibration frequency of the machine to achieve the effect of adjusting the operating speed and vibration intensity.

4. Water&Liquid filling device: It can realize the automatic filling of polishing liquid and appropriate amount of water according to the meter during the operation of the equipment.