Description

Centrifugal Dehydration Dryer

The centrifugal dryer, also called spin dryer, is suitable for rapid drying of hardware accessories, mechanical parts, electronic components, powder metallurgy parts, electroplated parts and other products that require surface dryness after finishing and polishing. It can avoid secondary oxidation and rust of the workpiece and improve the surface brightness of the product.

The machine is designed based on the principles of centrifugal dehydration and hot air drying. The dehydration and drying operations are performed simultaneously to eliminate water stains and marks, and the drying efficiency is high. First, the rotating action of centrifugal force throws excess moisture from the surface of the workpiece; next, the heating tube generates hot air, which flows through the dryer. Dry the parts thoroughly.

The work efficiency is high. Usually, it only takes about 5 minutes to get dry, watermark-free and water-stained workpieces.

It adopts a foot brake device to quickly stop the centrifugal barrel in the shutdown state after drying.

The movable dewatering inner basket is made of stainless steel and can be lifted out for easy loading and unloading of workpieces.

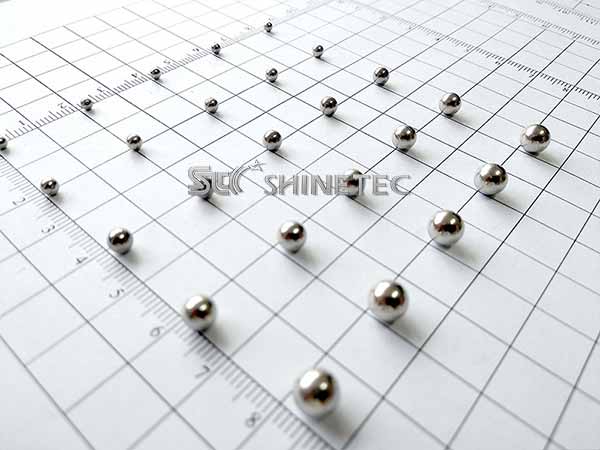

The difference from the vibrating dryer is that the working barrel of this model has a smaller capacity and is suitable for dehydration and drying of small-sized workpieces. There is no drying media in the barrel and no surface finishing effect.

Optional:

1. An independent control box can be configured to add more functional expansions, such as automatic temperature control, timing control, current overload protection, centrifugal barrel rotation speed, etc.

2. An additional safety switch will automatically cut off the power of the dehydration dryer when the cover is opened, which is safe and practical.

3. Equipped with a turbo fan, the hot air can be sucked out to speed up circulation and improve drying efficiency.