What is stainless steel media?

About Stainless Steel Media

- 1. What is stainless steel media?

- 2. What are the uses of stainless steel media?

- 3. What types of stainless steel media are there?

- 4. What shapes do stainless steel media have?

- 5. What are the specifications of stainless steel media?

- 6. Which parts can be polished with stainless steel media?

- 7. How do stainless steel media polish product parts?

- 8. What is the best stainless steel media?

- 9. Which finishing and polishing machine is suitable forv stainless steel media?

- 10. What are the benefits of polishing with stainless steel media?

- 11. Do stainless steel media require maintenance for daily use?

- 12. In which industries can stainless steel media be used for product parts and workpieces?

- 13. What are the benefits of using stainless steel media for tumbling polishing?

- 14. How long is the service life of stainless steel media?

- 15. Can brass parts be polished with stainless steel media?

- 16. Can nickel-plated metal parts be polished with stainless steel media?

- 17. Can stainless steel media be used for dry and wet finishing?

- 18. Do stainless steel media need to be dried when stored?

- 19. Will stainless steel media damage my parts?

- 20. Do stainless steel media require special lubrication?

- 21. Are stainless steel media magnetic?

- 22. What are the proportions of media, parts, and water when polishing with stainless steel media?

- 23. Where should stainless steel media be placed when stored?

- 24. How long does it usually take to polish with stainless steel media?

- 25. Can jewelry be polished with stainless steel media?

- 26. Why does the surface of the part become darker and lose its luster after being polished with stainless steel media?

- 27. Which stainless steel media should I buy?

- 28. Why do my product parts turn black after being polished with stainless steel media?

- 29. Do stainless steel media need to be cleaned before each use?

- 30. How much stainless steel media is required to complete a polishing process?

- 31. What is the best machine for polishing with stainless steel media?

- 32. Do stainless steel media need rust inhibitors?

- 33. Can other types of finishing machines be polished with stainless steel media?

- 34. Is polishing with stainless steel media faster than using other polishing media?

- 35. Can plastic parts and workpieces be polished with stainless steel media?

- 36. What is the price of stainless steel media?

- 1. What is stainless steel media?

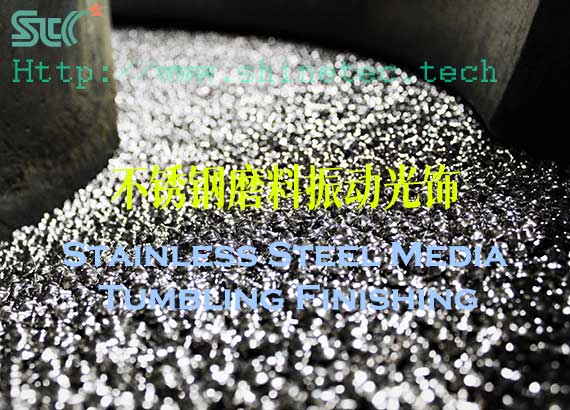

- As the name suggests, stainless steel media are tumbling media made of stainless steel. This is a kind of mass finishng, tumbling polishing, brightening and smoothing abrasive media mainly used in the finishing industry.

Stainless steel media act on your product parts and workpieces and have the functions of deburring, cleaning, degreasing, brightening, and mirror polishing. Most metal parts can obtain a shiny surface effect after polishing.

High-quality stainless steel raw materials produce high-quality stainless steel media. They have a long service life and can be used for a long time. They are the best choice for tumbling, mass finishing and polishing processes. At the same time, the impact of stainless steel media can improve the surface strength of product parts and repair surface defects. - 2. What are the uses of stainless steel media?

- Stainless steel media are widely used in the finishing and polishing industry of tumbling, vibrating, mass finishing and polishing. Specific applications are as follows:

2.1 Deburring. Stainless steel media also have the function of removing burrs. Some small burrs and sharp teeth on the edges of parts and hole walls can be chamfered and flattened by scraping with stainless steel media with sharp corners or edges to achieve the effect of removing burrs.

2.1 Turning tool marks removing. This process is similar to deburring. The turning tool marks left after the machining of parts can be removed by the impact and scraping of stainless steel media.

2.2 Polishing. The main function of stainless steel media is to brighten the surface of product workpieces. Through the tumbling and rotating motion of the machine, the high density stainless steel media impacts the surface of the part, changing the metallographic structure of the metal surface layer. The arrangement of the metal grains is reorganized to form a dense layer, which enhances the diffuse reflection of light, making the surface Becomes shiny and sparkling, achieving a near-mirror polished effect.

2.3 Degreasing. Through the combined use of stainless steel media and cleaning liquid, dust, sludge, and grease on the internal and external surfaces of parts can be removed. Manual cleaning of oil stains is a time-consuming and labor-intensive process. Using a tumbling finishing machine and stainless steel media for cleaning can improve the brightness and gloss of the surface of the parts while removing oil and stains. It is a process that gets twice the result with half the effort.

- 3. What types of stainless steel media are there?

-

International Standards 1Cr18Ni9 0Cr19Ni9 0Cr17Ni12Mo2 3Cr13 9Cr18 China 302 304 316 420 440C USA SUS302 SUS304 SUS316 SUS402 SUS440C JP X12CrNi188 X5CrNi189 X5CrNiMn18 X30Cr13 Germany 1.43 1.4301 1.4401 1.4028 - 4. What shapes do stainless steel media have?

- Stainless steel media for polishing come in a variety of shapes:

4.1 Sphere Ball. Stainless steel balls are the most commonly used stainless steel media, also called stainless steel beads. This is a polishing media with uniform size and smooth appearance.

4.2 Ballcone. Ballcone is also a commonly used stainless steel media, also called stainless steel ufo media, often mixed with stainless steel balls for polishing. Because the rounded edges on the outside can be polished into grooves, seams, dead corners and other parts of parts, it is very suitable for polishing product parts with complex irregular shapes.

4.3 Angle cut cylinder. Cutting an end face of the cylinder diagonally is also to polish some hard-to-reach parts. The cylinder part is suitable for polishing some parts with inner holes, teeth and other curved surfaces.

- 5. What are the specifications of stainless steel media?

- Stainless steel ball: 2mm-11 mm.

Ballcone: 1*3mm,2*4mm,3.5*5.5mm,4.5*7mm,6*8mm,8*11mm.

Angle cut cylinder: 2*8mm,3*8mm,4*8mm - 6. Which parts can be polished with stainless steel media?

- If your product parts are made of metal and have a hardness equal to or less than 304/302 stainless steel, then polishing with stainless steel media is the best choice. While polishing, stainless steel media can also remove surface oxide scale, turning tool marks and other defects on brass, copper, aluminum, zinc and other products.

- 7. How do stainless steel media polish product parts?

- Put the stainless steel media into the working barrel of the finishing polishing machine, add water and an appropriate amount of polishing liquid. After the machine is started, the stainless steel media and the workpiece will have a tumbling and rotating motion in the machine. The abrasive media and the parts rub against each other, which will cause the surface to change. Scrape off the scale, burrs, residue, etc. In addition, stainless steel media have an impact force on the parts, which will change the grain structure arrangement on the surface of the parts, forming a dense layer and achieving a shiny surface effect.

- 8. What is the best stainless steel media?

- The best stainless steel media should look like this:

Fully self-grinding, the curved surface is round and smooth, and the cut surface is neat and straight.

The specifications and sizes are uniform and the dimensional tolerances are reasonable.

The material matches the stainless code and the anti-rust performance meets the standard.

If you don’t know where there is the best stainless steel media, please follow our ShineTec related products. We are committed to becoming the best brand in the stainless steel media industry.

- 9. Which finishing and polishing machine is suitable forv stainless steel media?

- ShineTec recommends using a vibratory polishing machine with stainless steel media for polishing. The reasons are as follows:

9.1 To achieve a good polishing effect with stainless steel media, the product parts need to be put into as much tumbling media as possible. The vibratory finishing machine can be equipped with a high-power vibration motor and a large-capacity working chamber to obtain a larger amplitude, allowing the workpiece to fully tumble in the machine and collide with the abrasive media to obtain a better surface effect.

9.2 Because the size of the centrifugal barrel is limited, the centrifugal barrel finishing machine has a small loading capacity of tumbling media and is not very efficient. Moreover, due to the large proportion of stainless steel media, the centrifugal force generated when the barrel is loaded with abrasive media and rotates at high speed will increase many times, which greatly exceeds the design strength of the centrifugal barrel finishing machine and creates potential safety risks.

9.3 The barrel of the centrifugal disc finishing machine also does not meet the capacity requirements compared to the vibrating finishing machine. If it is operated at full load, it will greatly exceed the design strength of the machine, and it is not suitable to use stainless steel media to polish product parts.

9.4 The polishing efficiency of the tumbling barrel finishing machine is too slow, and the design capability of the machine itself is not suitable for heavy-duty use, and it is not suitable for polishing with stainless steel media.

- 10. What are the benefits of polishing with stainless steel media?

- If you don’t know how to improve the surface gloss and brightness of metal product parts and workpieces, then using stainless steel media for tumbling and polishing is the best polishing process and method.

10.1 High polishing efficiency. Compared with polishing media such as high-alumina porcelain media, high-density porcelain media, and zirconia balls, stainless steel media have the highest specific density (7.8 g/cm3) and can obtain the highest brightness in the shortest time.

10.2 High cleaning efficiency. Stainless steel media have very little wear and do not pollute the surface structure of metal product parts. With the assistance of cleaning agents and brighteners, they can fully clean away oil, sludge, and impurities on the surface of workpieces automatically, in large quantities, quickly, and solve the problem of manual cleaning. Time-consuming and labor-intensive problem.

10.3 Non-destructive polishing. 不Stainless steel media have no cutting force, will not finish the surface with great force, and will not affect the dimensional accuracy of the product. It is a non-destructive polishing process.

10.4 Extra long service life. Stainless steel media have almost no wear, and a single purchase can last almost a lifetime. There is almost no wear cost, which can greatly reduce your direct polishing costs.

10.5 Easy to use. Ceramic polishing media will stick to each other, break, and become dirty after use. They need to be fully self-polished and cleaned before they can be used again. There are no breakage or bonding issues with the stainless steel media. After polishing, you only need to simply rinse it with water and it can be used continuously again. - 11. Do stainless steel media require maintenance for daily use?

- Good maintenance habits can extend the service life of stainless steel media. Although stainless steel media is an tumbling polishing media that is easy to use and store, its service life will be accelerated if not properly maintained.

11.1 Correct usage. After polishing, if it is not used for a long time, you need to rinse the stainless steel media with water and dry it before storing it.

11.2 Proper mixing ratio of stainless steel media, product parts and polishing liquid. A corresponding ratio needs to be maintained among the above three. In order to save procurement costs, many people want to use as little stainless steel media as possible and put more product workpieces. However, too little abrasives will cause the product parts to collide with each other during polishing or the workpieces to directly scratch the working chamber wall of the machine and damage the lining PU. This results in reduced polishing efficiency, reduced polishing quality and possible damage to product parts and machines.

11.3 Replacement of damaged stainless steel media. Ensure that every one of stainless steel media in the machine is intact. If some of the media are deformed or damaged, the damaged media must be replaced immediately. The damaged media surface will produce cracks, edges, and cutting edges. These parts will affect the surface effect of product parts during polishing, and even damage the product. - 12. In which industries can stainless steel media be used for product parts and workpieces?

- Stainless steel abrasives can be used for finishing and polishing metal parts or workpieces in most industries.

12.1 Professional finishing and polishing processing job shop. Stainless steel media are the most cost-effective tumbling media in the polishing process of polishing job shop. There is no wear on the abrasive, and only a small amount of chemical polishing liquid needs to be added for each processing to complete the polishing process. This abrasive media is available in many polishing processing job shop.

12.2 Jewelry industry. After long-term storage or use, the surface of jewelry will produce an oxide layer, which will darken and turn black. Polishing with stainless steel media can restore jewelry to its original luster.

12.3 Auto parts industry. The auto parts industry is an area where stainless steel media are widely used. Includes deburring and polishing applications. Such as engine cylinder heads, pistons, motorcycle wheels, mufflers, fasteners, gears and other products. It also has a good polishing effect on the refurbishing of some forged or cast auto parts.

12.4 Aerospace and defense fields. The strength and reliability of product parts in the aerospace and defense fields are the most critical indicators. The impact of stainless steel media during the polishing process can increase the strength of the product surface and produce a uniform surface polishing effect.

12.5 Medical equipment and devices. Product parts for the medical device and device industry must be guaranteed to be zero-defect. After metal parts are polished with stainless steel media, the strength and surface quality of the product will be improved. For example, titanium, chromium, stainless steel, cobalt and other materials and their alloy products are very suitable for polishing and brightening with stainless steel media.

12.6 Motorcycle Accessories. Motorcycle accessories require high-quality products and glossy product surface quality. Using stainless steel media for polishing can quickly achieve satisfactory polishing results. - 13. What are the benefits of using stainless steel media for tumbling polishing?

- 13.1 Improve the wear resistance of parts. Stainless steel media can remove components from the microstructure that affect the corrosion resistance of product parts. It can completely remove the oxide layer on the surface, eliminate cracks and other defects on the surface of parts that are easily affected by oxidation, and improve the overall corrosion resistance.

13.2 Improves strain hardening of parts. After tumbling finishing and polishing with stainless steel media, the surface hardness of the parts can be increased. Compared with unpolished parts, the surface hardness can be increased by 50-100%.

13.3 Brightening and burnishing effect. Stainless steel media can not only improve the strength of parts, but also improve the brightness and gloss of the product surface. After the fine polishing process, it can achieve an effect close to mirror polishing. - 14. How long is the service life of stainless steel media?

- If you take appropriate daily maintenance measures, you can use it for a long time. Of course, poor usage habits will definitely reduce the use time of stainless steel media. In comparison, compared to porcelain polishing media, its service life is far longer than other abrasive media.

- 15. Can brass parts be polished with stainless steel media?

- Yes, brass parts can be polished with stainless steel media.

- 16. Can nickel-plated metal parts be polished with stainless steel media?

- Yes, stainless steel media can be used to polish nickel plated metal parts. However, the polishing time needs to be shortened to 40-60% of the ordinary polishing time.

- 17. Can stainless steel media be used for dry and wet finishing?

- Stainless steel media cannot be used for dry polishing. During the polishing process of product parts, metal shavings, oil stains and other impurities will be produced. If these sludge is not cleaned during the finishing process, it will adhere to the surface of the product to form a layer of oil stains, making the parts black and dull. The result is that the workpiece will become darker. The darker you throw it, the brighter it will never be.

- 18. Do stainless steel media need to be dried when stored?

- If you need to store it for a long period of time, such as months or years, you need to let the stainless steel media dry before packaging and storage. If it is for a short period of time, it is not necessary because stainless steel itself is rust-proof and anti-corrosion.

- 19. Will stainless steel media damage my parts?

- As long as the proper matching ratio of media, water, and polishing liquid is maintained during the polishing process, and the size of the media matches the size of the parts, there will be no damage.

- 20. Do stainless steel media require special lubrication?

- Unnecessary. When polishing with stainless steel media, you only need to add clean water and an appropriate amount of polishing liquid. There is no need to add external lubricating grease and other substances.

- 21. Are stainless steel media magnetic?

- Yes, stainless steel media are weakly magnetic. You can use this feature to use magnets to collect media scattered on the floor around the machine during the polishing process.

- 22. What are the proportions of media, parts, and water when polishing with stainless steel media?

- Generally we recommend this matching rate:

Media : Parts : Water = 3 : 1 : 2 - 23. Where should stainless steel media be placed when stored?

- Please place stainless steel media in a dry, clean indoor space. Although stainless steel media themselves are anti-corrosive and anti-rust, low-grade materials will also rust if they are exposed to humid, acidic and alkaline environments for a long time.

- 24. How long does it usually take to polish with stainless steel media?

- It usually takes about 30 minutes to polish with stainless steel media. If the surface brightness does not improve significantly after more than 1 hour, extending the polishing time will have no effect.

- 25. Can jewelry be polished with stainless steel media?

- Yes, jewelry can be polished with stainless steel media.

- 26. Why does the surface of the part become darker and lose its luster after being polished with stainless steel media?

- When polishing with stainless steel media, it is found that the surface of the part becomes black and dark because the oil on the surface of the media or the carbon in the impurities is deposited on the surface of the product. The solution is to clean the stainless steel media with cleaning liquid before polishing.

- 27. Which stainless steel media should I buy?

- 27.1 Choose the appropriate stainless steel media according to the shape and size of your product parts and workpieces. Please do not use large-sized media to polish small-sized parts to avoid damage. If you use small-sized media to polish large-sized parts, it will take more man-hours and have a big impact on the service life of the media.

27.2 Make sure that the internal and external surfaces of your parts, as well as holes, gaps, corners, etc., can be polished with stainless steel media.

27.3 According to the actual usage environment of your product. If your use environment contains acid and alkaline substances, you need to choose high-grade stainless steel media. The following is the corrosion resistance of various grades of stainless steel media:

440C < 420 < 302 < 304 < 316 - 28. Why do my product parts turn black after being polished with stainless steel media?

- The main reason is that the stainless steel media needs to be pre-cleaned before polishing. If there are some residual brighteners, sludge, debris and other impurities attached to the media surface after the last polishing, polishing again will contaminate your product parts with these impurities, causing the product surface to turn black.

- 29. Do stainless steel media need to be cleaned before each use?

- We recommend cleaning stainless steel media once before use. This ensures that the surface of the part will not turn black or dull during the polishing process.

- 30. How much stainless steel media is required to complete a polishing process?

- Depending on the machine capacity used. It is recommended that the total volume of materials does not exceed 2/3 of the working chamber.

The general ratio of parts to media is 1:3, and this ratio can also be adjusted according to the shape and size of the workpiece. - 31. What is the best machine for polishing with stainless steel media?

- We recommend using a vibratory polishing machine to polish with stainless steel media. The advantages are: easy to load and unload, you can check the polishing effect at any time, large loading capacity, and simple to use.

- 32. Do stainless steel media need rust inhibitors?

- Unnecessary. Because stainless steel media are made of anti-corrosion and anti-rust stainless steel materials, there is no need to add additional anti-rust liquid.

- 33. Can other types of finishing machines be polished with stainless steel media?

- Centrifugal disc finishing machines, centrifugal barrel finishing machines, and barrel tumbling finishing machines can all use stainless steel media for polishing. It’s just that other machines need to reduce the loading of media when polishing. Generally, the amount of media is reduced by half compared to using porcelain polishing media.

- 34. Is polishing with stainless steel media faster than using other polishing media?

- Yes, because the density of stainless steel media exceeds that of porcelain polishing media, it is easier to obtain a bright surface effect in a shorter time.

- 35. Can plastic parts and workpieces be polished with stainless steel media?

- No. The material of plastic products is not suitable for deburring and polishing with stainless steel media. You can use ceramic deburring media or resin media to remove burrs, and use brightening media to polish the brightness.

- 36. What is the price of stainless steel media?

- The price of stainless steel media varies according to grade, shape, and size. The larger the size, the lower the price. Of course, its price will be much higher than tumbling media such as brown corundum ceramic media, white corundum ceramic media, and silicon carbide ceramic media. However, in terms of service life, the cost of using stainless steel media is far lower than that of other abrasive media. Maybe you are concerned about where to find the cheapest stainless steel media, please contact us now, ShineTec will give you a satisfactory offer.