Deburring, descaling and mirror polishing technology method for deep drawing stamping parts of stainless steel

How to remove burrs, oxide scale, stretch lines and mirror polish the stainless steel deep drawing stamping parts?

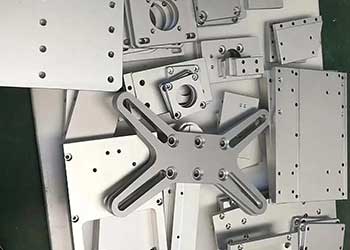

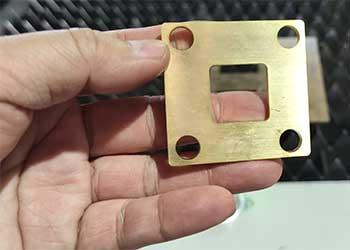

Metal drawing stamping process is a common metal forming process. The difference between it and the standard stamping process is that standard stamping does not significantly change the depth of the formed product, while drawing (stretching) stamping generally significantly increases the depth of the formed product. Most of the daily necessities we use are made of metal by deep drawing and stamping processes. Today we will share a case of reducing surface roughness and mirror polishing of parts made of 304 stainless steel plates after deep drawing and stamping. This polishing process solution is also suitable for deburring, descaling, removing stretch marks, wrinkles, and mirror polishing of hardware drawing and stamping parts made of other materials such as aluminum alloy, carbon steel, copper, or nickel-titanium alloy.

- jerrylu

- 2024-06-07

- 0 Comments

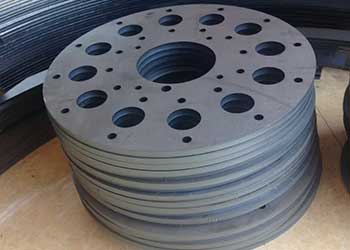

1. The stainless steel deep drawing stamping parts before polishing

Materials:

304 stainless steel

Appearance:

surface burrs, stretch marks

Shape:

hollow cylinder

Size:

Ø50*15 MM

Pre-polishing process:

deep drawing stamping

Post-polishing process:

chrome plating

2. Finishing and polishing requirements

- deburring, de-stretch marks,roughness reduced from Ra0.5 to below Ra0.2

- surface mirror polishing

3. Polishing process details of stainless steel deep drawing stamping parts:

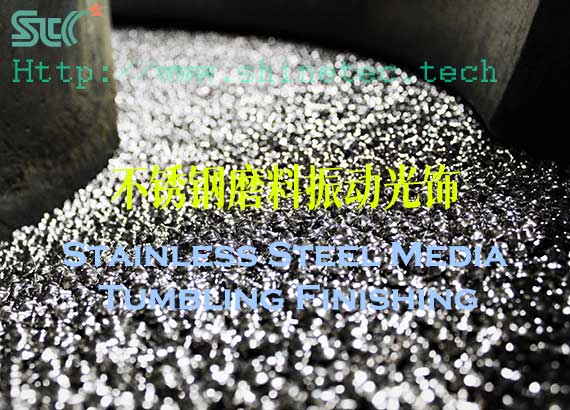

| Porcess steps: | (1) deburring, descaling for rough finishing | (2) reduce roughness for fine finishing | (3) mirror polishing |

|---|---|---|---|

| Machine and equipment | vibratory bowl finisher | vibratory bowl finisher | mirror polishing machine |

| Speed | highest | highest | highest |

| Abrasive Media | tri-angle silicon carbide deburring media | cone polyester media | mirror polishing media |

| Abrasive media to workpiece | 4:1 | 4:1 | 8:1 |

| Chemical Compound | finishing compound | polishing compound | polishing paste |

| Water | appropriate amount, liquid level does not exceed abrasive media | appropriate amount, liquid level does not exceed abrasive media | no |

| Polishing time | 120 minutes | 60 minutes | 180 minutes |

| Remark | parts separated and picked up automatically, rinsed with water | parts separated and picked up automatically, rinsed with water | high-speed mirror polishing |

4. The stainless steel deep drawing stamping parts after polishing

5. Additional instructions

- This stainless steel deep drawing stamping hardware parts product is formed from stainless steel thin plate through deep drawing of mold. There are sharp burrs on the upper end after cutting, but the wall thickness of the finished product is very thin, which can easily cause deformation of the workpiece during polishing. Therefore, the rough finishing machine adopts vibrating bowl finishing machine, which has moderate finishing force and high cutting efficiency. Abrasive media uses heavy-cutting triangular silicon carbide deburring media, which can quickly remove burrs, stretch line marks and wrinkles.

- Fine finishing uses light cutting force cone-shaped plastic media, also called resin media. This abrasive media has small grit size and light weight, will not cause deformation of the workpiece, and can further reduce the surface roughness.

- The last step after fine finishing is to use a mirror polisher with precision finishing media to enhance the brightness and mirror polishing.

6. Final summary

- In this case, we demonstrated the process of automated deburring, descaling, removing stretch mark lines and mirror polishing of the outer surface of a hardware component product formed by deep drawing and stamping of a 304 stainless steel plate.

-

If you need professional technical support for deep drawing stamping parts, products or the following products made of stainless steel, aluminum alloy, copper alloy, carbon steel, etc., deburring, descaling, finishing and polishing, you can refer to the above cases:

How to deal with stamping stretch marks

Methods for deburring by drawing stamping

Principles of deburring by stretching stamping

How to deburr by stamping

What does it mean to a burred stamped part

What is the best tool for deburring a stamped part

Process flow of stretching stamping polishing

Polishing of stamped parts

What is the best material for deep drawing

Deep drawing forming process