How to deburr, descale, polish laser cutting workpieces?

How to remove burrs, flash, scale, chamfer, oil and dirt on laser cut parts? ShineTec is your reliable service manufacturer.

The mass finishing and polishing machines, equipments and tumbling abrasive media we produce can well meet the surface finishing treatment requirements of special-shaped laser cutting workpieces, water jet cutting parts, plasma cutting parts, and flame cutting parts. Depending on your actual production capacity and operating environment, we can help you achieve the best product finishing and polishing process. No burrs, No flash on parts. Efficient equipment and high-quality finishing abrasive media ensure the final surface quality of your products.

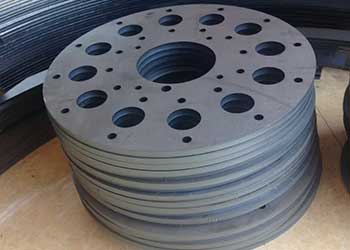

Deburring, deflashing of carbon steel and alloy steel laser cutting parts

For parts such as stainless steel and high carbon steel, Ceramic Deburring Media with heavy cutting force are generally used, and a vibrating finishing and polishing machine is used with chemical finishing compound to achieve high finishing efficiency, strong processing capabilities, and a lower surface roughness.

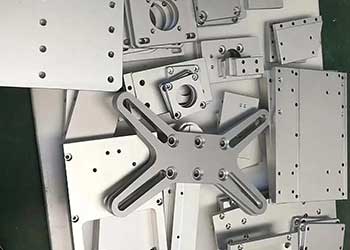

Deburring,deflashing of aluminum-magnesium alloy laser cutting parts

Because the product material is relatively soft, high-density, color-contaminated Ceramic Deburring Media are not suitable for polishing this aluminum-magnesium alloy product. The best tumbling media is Resin Media, also called Plastic Media, Polyester Media.

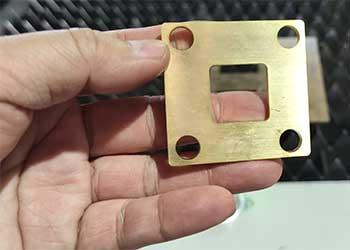

Deburring, deflashing of brass and copper laser cutting parts

Also because the product has a soft texture, resin tumbling media are also needed to deburr and deflash. After finishing and polishing, the surface color of the product can maintain its original color, and no contamination by ceramic tumbling media will occur.

Deburring, deflashing of stainless steel plate laser cutting parts

Laser cutting workpieces made of thin steel plates and galvanized sheets also need to use high-cutting ceramic deburring media, with a vibratory finishing and polishing machine with Finishing Liquid Compound. If the workpieces stick to each other, Chemical Compound need to be added to prevent sticking.

Deburring, deflashing of sheet metal laser cutting parts

Using a ceramic media such as a triangle with sharp corners or a beveled cylinder, you can deburr and polish deep into the corners, inner holes, gaps and other parts of the workpiece.

Deburring, deflashing of plastic and acrylic laser cutting parts

Laser cutting workpieces made of plastic or acrylic are suitable for polishing with high density porcelain tumbling media. This tumbling media does not contain abrasive sand, has no cutting force, and will not scratch the surface of the product.

- 1. What are laser cut parts?

- 2. Why do laser cut parts need to be deburred?

- 3. Can you explain the method of deburring from laser cutting workpieces?

- 4. What kind of equipment is the laser cutting workpiece deburring machine?

- 5. What are the advantages of laser cutting parts finishing and polishing machines?

- 6. What types of laser cutting parts deburring machines does ShineTec have?

- 7. What deburring abrasive media are used in laser cutting parts deburring machines?

- 8. Which products’ laser-cut parts can be used with this tumbling finishing deburring and polishing machine?

- 1. What are laser cut parts?

- Laser cutting parts are workpieces produced using laser cutting processing technology. It is used in spare parts for products with high precision requirements in various industrial fields.

- 2. Why do laser cut parts need to be deburred?

- Laser-cut parts produced during processing must undergo surface treatment processes such as deburring and polishing.

The benefits of applying this finishing process are as follows:

2.1 Remove oxide layer.

Laser cutting uses gases such as oxygen or carbon dioxide as assistance. These gases will form an oxide layer on the surface of the product during high-temperature cutting. It may corrode or rust the parts, so you must polish these cutting parts to remove the oxide layer.

2.2 Improve product appearance quality.

The appearance of a product affects its quality. If you are a practitioner of machined parts, using the deburring and finishing process can provide a beautiful and uniform appearance to the workpiece.

2.3 Repair product surface quality.

The laser cutting process may cause certain appearance defects to the workpiece, such as silk lines, cracks, pitting, etc. Through finishing and polishing, these defects can be repaired, thereby improving product yield and reducing production costs.

2.4 Chamfer processing.

Laser cutting will produce sharp edges or corners, which may cause harm to users during use.

After chamfering, sharp edges can be removed and sharp corners can be smoothed and rounded. It can also reduce product stress, which affects product durability and quality stability.

2.5 Produces a special matte effect.

Some products may require a matte finish. This demand can be met by using appropriate tumbling abrasive media and correct finishing and polishing processes.

2.6 Improve security.

Flashes, sharp edges, and sharp corners on the surface of the workpiece may cause harm to the user. Therefore, it is necessary to use a deburring and finishing machine for polishing in the subsequent process to improve the surface quality of the product. - 3. Can you explain the method of deburring from laser cutting workpieces?

- Currently, many laser-cut parts are still polished manually. For example, traditional deburring methods such as sandpaper, power tools with grinding heads, belt sanders, and grinding wheels are used.

These backward polishing methods are inefficient, not environmentally friendly, and also bring many safety hazards.

Some new deburring processes include ultrasonic, thermal energy, electrochemical, sandblasting, shot blasting and other methods. Each has its own characteristics and limitations.

The tumbling finishing and polishing process we currently provide is a low-cost, high-volume, and high-efficiency mechanized deburring and polishing method, which is especially suitable for some special-shaped laser cutting parts with complex cavities. - 4. What kind of equipment is the laser cutting workpiece deburring machine?

- Laser cutting parts polishing machine is a machine used to deburr, descale, chamfer, clean, degrease, and polish and brighten laser cut products. Using the right tumbling abrasive media and choosing the right machine type will make your process more efficient. At the same time, it can also reduce labor costs, reduce labor intensity, and improve production efficiency.

- 5. What are the advantages of laser cutting parts finishing and polishing machines?

- The benefits of laser cutting parts deburring and polishing machines are as follows:

5.1 Lower processing costs. Manual deburring requires high labor costs, more tools and abrasive material losses. Our finishing and polishing machine for laser cutting is a one-time investment. Later, you only need to purchase some tumbling media, chemical compound liquid regularly. Only very little manual participation is required during the processing, so labor costs will be greatly reduced.

5.2 Save time. It is obvious that machine deburring and polishing can greatly save operating time compared to manual polishing. Your productivity can be greatly improved.

5.3 Non-destructive surface treatment. Use suitable matching tumbling finishing media and choose the correct mass finishing equipment. After completing the polishing processes such as deburring and descaling, your product workpiece will not change in shape, position and size. It is a lossless process. If it is polished by hand, due to the different handling strength of each workpiece, it may have an impact on the size of the product, and each one is not uniform.

5.4 Get the best surface quality. The quality of product appearance determines the quality of the product. Manual polishing cannot achieve a consistently stable product surface quality. But a polishing machine can give you a consistent look. Finishing time and surface roughness level can be controlled, helping you to stand out in the fierce market competition.

5.5 Save labor. At present, the labor cost of product polishing process accounts for a large proportion of the overall product cost. ShineTec’s finishing and polishing machine allows a single worker to perform multiple batches of mechanized deburring, descaling and polishing, which will save a lot of labor costs and greatly reduce labor intensity.

5.6 High-volume polishing. Our finishing and polishing solutions are characterized by high-volume, high-efficiency, mechanized automatic finishing. Laser cutting parts of different shapes and sizes can be processed in the same polishing machine. If combined with automated assembly lines, your production efficiency and product quality can be greatly improved.

5.7 Extremely low maintenance costs. The daily maintenance cost of the machine and the loss of tumbling media are the most important factors for business owners to consider. ShineTec’s finishing and polishing machines have almost no maintenance costs. In addition to regularly adding a little lubricant to the motor, there are no other special tools that need to be purchased.

5.8 No specially trained operators are required. Manual finishing and polishing requires special training for operators first. This is a high labor cost and an uncontrollable link in the production process. The mass finishing machines we provide are very simple to operate. Workers only need to load and unload materials. The polishing process of the machine does not require manual participation.

5.9 Safe production environment. Laser-cut parts may have sharp corners, burrs or flash edges, which may cause harm to front-line workers. Debris generated during manual polishing may also enter people’s eyes or cause skin allergic reactions. Using finishing and polishing machines can avoid these phenomena. Provide production workers with a safe and reliable production working environment.

5.10 Improve the adhesion of electroplating, paint and coatings. Some laser-cut parts may require electroplating, painting or coating treatment in the final stage. If polished by hand, the appearance of the product will be inconsistent, resulting in unstable surface quality of the finished product. After using our tumbling finishing and polishing, there will be a uniform surface quality before subsequent surface treatment, and a reliable and stable product quality will be obtained later. - 6. What types of laser cutting parts deburring machines does ShineTec have?

- ShineTec provides different tumbling finishing and polishing machines that can be used to polish laser cut parts. They are vibratory/vibrating deburring and finishing machines, centrifugal barrel finishing machines, centrifugal disc finishing machines, and barrel tumbling finishing machines. Depending on the material, shape, specification and size of the workpiece, we can select the correct machine model and matching ceramic deburring media, porcelain polishing media and other tumbling media to meet your process requirements.

6.1 Vibratory Finishing Machine. Vibration type, also called vibrating finishing and polishing machine, is the most commonly used equipment for deburring and polishing laser cutting parts. It is characterized by strong applicability, large processing capacity, easy operation, convenient loading and unloading, and controllable process. Generally, small and medium-sized special-shaped workpieces can be processed. The disadvantage is that it is not easy to penetrate deep into the cavity.

6.2 Centrifugal Barrel Finishing Machine。 The centrifugal barrel finishing type, is a device suitable for finishing and polishing some small-sized laser cutting workpieces. It is characterized by strong cutting force, short processing time, and the ability to penetrate deep into the inner holes and gaps of the workpiece. The disadvantage is that the processing capacity is not large at one time, and loading and unloading is time-consuming.

6.3 Centrfugal Disc Finishing Machine。 The centrifugal disc finishing machine is suitable for processing some laser cutting workpiece products with large burrs. It is characterized by the strongest cutting force, short processing time and easy loading and unloading. Generally speaking, compared with vibratory polishing machines, the finishing and polishing efficiency can be increased by about 30 times. The disadvantage is that it is not suitable for some thin laser cutting parts and is easy to deform or get stuck in the gaps of the machine chassis.

6.4 Tumbling Barrel Finishing Machine. Also called rotary barrel polishing machine. It is suitable for parts with high surface polishing brightness and gloss requirements. It is characterized by slow work and careful work, combined with special abrasive media, such as walnut shells, corn cobs, wood, bamboo chips and other plant abrasives, and polishing paste, which can bring a mirror-like shiny surface effect. The disadvantage is that the processing time is slow and the efficiency is low. Some parts may need to be processed for several days at a time. It is also not suitable for some easily deformed laser cutting workpieces. - 7. What deburring abrasive media are used in laser cutting parts deburring machines?

- The tumbling media used for finishing and polishing laser cutting parts are also called mass finishing media. ShineTec offers a wide range of abrasive media. The factors that affect the quality of abrasives mainly include cutting force, wear resistance, specific gravity density, hardness, appearance size, color and other indicators. High-quality raw materials and scientific production process control bring high-quality abrasive media. The main types are as follows:

7.1 Brown Corundum Ceramic Deburring Media. Brown corundum ceramic media is a commonly used abrasive material used for deburring, descaling, deflashing and finishing of laser cutting parts. Suitable for hard metal parts. The deburring ceramic media provided by ShineTec are available in triangular, cylindrical, spherical, conical, three-star, oval, pyramid, tetrahedral and other shapes. Each shape has different specifications and sizes. Each abrasive media also has different cutting force levels. Heavy cutting force deburring media are used for workpieces that require a lot of finishing and cutting force, and light cutting force deburring media are used for some product workpieces that require a lot of smoothness.

7.2 High Alumina Porcelain Media. High-alumina porcelain media do not contain brown corundum sand with strong cutting force. Therefore, this tumbling polishing media has no cutting force and cannot be used for deburring, descaling and other processing. Because of the high alumina content, the polishing abrasive media formed after final sintering has a large specific gravity, dense internal structure, and strong hardness. It is suitable for polishing processes that improve the surface brightness of laser cutting workpieces. The greater the specific density, the higher the surface brightness of the treated product. The appearance color is porcelain white, and the shapes are generally spherical, triangular, cylindrical, oval, etc.

7.3 Resin Media。 Tumbling resin media are also called Plastic Media, Polyester Media. Because they have a moderately elastic surface, they are suitable for polishing and polishing laser cutting parts produced from soft metals such as aluminum alloys. Resin grinding stone is an abrasive material made of resin mixed with corundum sand powder through a curing reaction. It is also suitable for deburring and polishing workpieces made of materials such as copper and plastic. ShineTec can provide resin abrasives in conical, pyramid, triangular, three-star, bullet and other shapes. Brown corundum sand containing different mesh numbers can bring different cutting forces, and can also be divided into heavy cutting, medium cutting, and light cutting grades.

7.4 Stainless Steel Media。 This polishing media is made of stainless steel. Because it has no cutting force and a density of up to 7.8 g/cm3, it is also used to polish the surface brightness of laser-cut parts. The specific gravity is more than three times higher than that of high-alumina porcelain polishing media, and the surface brightness obtained after polishing is also far superior to that of high-alumina porcelain polishing media. The shapes include ball, ballcone (ufo), and pin shapes, which are suitable for brightening metal workpieces.

7.5 Mirror Polishing Media. It is mainly produced by processing walnut shells, corn cobs, cork pellets, bamboo chips, etc. In addition to their finishing and polishing functions, walnut shells and corncobs are also used to dry cleaned workpieces in a vibration dryer because of their strong water absorption. Vegetable tumbling media are mainly used to polish the surface brightness of laser cutting parts. When used in conjunction with a barrel tumbling polishing machine, a mirror-like bright effect can be achieved. - 8. Which products’ laser-cut parts can be used with this tumbling finishing deburring and polishing machine?

- The laser cutting parts polishing machine provided by ShineTec can handle workpieces made of the following materials:

8.1 Stainless steel laser cutting parts. This is the most commonly used workpiece material. Used in healthcare, automotive parts, electronics, machinery and other industries.

8.2 Aluminum alloy laser cutting parts. For example, the framework of digital products.

8.3 Laser cutting parts in copper. Brass is easily oxidized in the air and turns black. Its original appearance can be restored by polishing and brightening.

8.4 Plastic laser cutting parts. Used in medicine, automobile, aviation, electronics and other industries.

8.5 Thin sheet laser cutting parts. It is easy to form sharp edges after laser cutting, which also require polishing and rounding.

8.6 Bending laser cutting parts. Triangle tumbling media are very suitable for deburring and polishing products.

8.7 Acrylic laser cutting pieces. Used in construction, advertising, machinery and other industries.

8.8 Carbon fiber laser cutting parts. Most carbon fiber products are cut using lasers.

8.9 Carbon steel laser cutting parts. This product is very versatile.

8.10 Alloy steel laser cutting parts. Such as chromium alloy, manganese alloy, tungsten alloy, titanium alloy and other components.