What should we do if the burrs cannot be removed completely when the edges are curled, turned over or collapsed?

Deburring, descaling, chamfering and polishing process of CV joint for automobile parts

The CV joint is an important component of the ball cage universal joint, a steering component of the car. On its drum-shaped side wall, six window holes are milled by CNC to install the steel balls responsible for rotation. If there are burrs on the inner wall of the window hole, then over time, the car will make a “clicking” noise during driving or turning. Therefore, the last process in the product production process is deburring and finishing. The commonly used polishing process is to use the vibrating deburring process to put the CV joint into the working bowl of the vibratory finisher for batch deburring. One disadvantage of this process is that the burrs on the edge of the window hole will have a flanging and curling phenomenon, which cannot be removed cleanly; at the same time, collisions between products will cause bumps and wounds. Today we will share how to improve and optimize the process of a 20 chromium manganese titanium CV joint product to solve the problem of unclean burr removal and bumps on the surface of the workpiece. This finishing process method is also suitable for other deburring, deflashing processes such as vibratory, centrifugal barrel, disc finishing where the burrs are not removed cleanly, and the collision between workpieces causes bumps and needs to improve and adjust the finishing and polishing process.

- jerrylu

- 2024-06-08

- 0 Comments

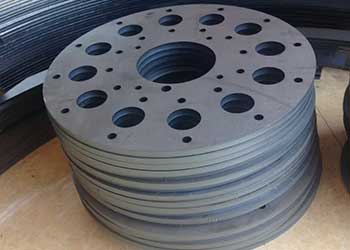

1. The CV joint before vibratory deburring, finishing, polishing

Materials:

20 chromium manganese titanium(20CRMNTI)

Appearance:

burr flanging, curling

Shape:

special-shaped

Size:

Ø65*35 MM

Pre-polishing process:

quenching

Post-polishing process:

packing

2. Finishing and polishing requirements:

- deburring

- No burrs, no bruises

3. Optimization and adjustment of cv joint deburring and polishing:

| Process steps: | (1) deburring |

|---|---|

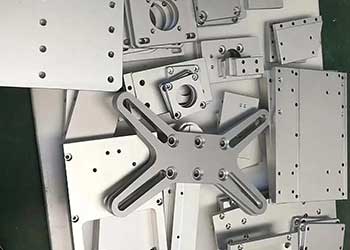

| Machine and equipment | centrifugal barrel deburring machine |

| Speed | highest |

| Abrasive Media | angle cut triangle ceramic tumbling media |

| Abrasive media to workpiece | 4:1 |

| Chemical compound | finishing liquid |

| Water | appropriate amount,the liquid level is 20mm above the abrasive media |

| Polishing time | 10 minutes |

| Remark | parts picked up manually, rinsed with water |

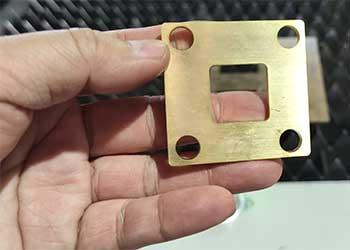

4. Deburring effect comparison after optimized process

5. Additional instructions

- 20 chromium manganese titanium (20CRMNTI) is a high-quality carburizing steel, which is often used to manufacture transmission parts of automotive parts. It has high strength and toughness, but the commonly used vibratory deburring process often has problems such as incomplete burr removal and collision of workpieces. After optimization, the special high-speed centrifugal barrel finishing machine is now used, which has strong finishing force, high cutting efficiency, and uses special anti-collision jigs and fixtures, thus avoiding the problem of collision between parts. Rough finishing uses heavy cutting force angle cut triangle ceramic deburring media, which can achieve the effect of rapid deburring.

6. Final summary

- In this case study, we demonstrate the automated deburring, finishing and polishing process of the surface of a 20CRMNTI cv joint of automotive parts.

- If your product workpiece has burrs, curled edges, collapsed edges, etc. that cannot be removed cleanly, or if the workpieces collide with each other and cause bumps and scratches, and other finishing and polishing problems require professional technical support, you can refer to the above case.