According to the source, abrasives can be divided into two categories: natural abrasive media and artificial finishing media.

2.1 Natural abrasive media include diamond, natural corundum (also called emery), garnet, quartz sand, diatomaceous earth, pumice, flint, silica, feldspar, chalk, lime for polishing, etc.

2.1.1 Diamond. Diamond is the hardest substance currently known. The main ingredient is carbon, which is expensive because of its limited origin. Mainly used for manufacturing resin, ceramic or metal bonded abrasive tools. Diamond has a sharp shape and is the best abrasive tool for grinding hard and brittle materials such as cemented carbide, optical glass, and ceramics. It has a better polishing effect on alloys of different phases with huge differences in soft and hard. In addition, diamond polishing abrasive media have the characteristics of long finishing life, high cutting ability, and strong wear resistance. However, because it is easily carbonized at 700℃~800℃, it is not suitable for finishing steel materials and ultra-high-speed grinding.

2.1.2 The main components of emery are aluminum oxide (Al2O3), a small amount of iron oxide (Fe2O3) and other impurities. It can be used for finishing and polishing all metals.

2.1.3 Garnet is the oldest type of polishing abrasive media. It was called Ziyawu in ancient China. It has been used to grind gemstones since the Bronze Age. It gets its name because the crystal particles are shaped like pomegranate seeds. It is mostly used for sandblasting, waterjet cutting, manufacturing coated abrasive tools, filter materials, wear-resistant floor aggregates, etc. It is used in hardware, steel, castings, ceramics, aluminum, wood, and leather industries.

2.1.4 The main component of quartz sand is SiO2, which is the earliest grinding wheel material and can be used for grinding, polishing, tumbling and sandblasting. The main component of diatomite is also SiO2, which is an ingredient in the manufacture of polishing powder and whetstone. Suitable for finishing and polishing soft metals such as brass, aluminum, and zinc.

2.1.5 Pumice comes from volcanoes and is the raw material for making polishing powder. Suitable for finishing and polishing soft metals and their alloys, wood, glass, plastic, leather, etc.

2.1.6 Flint, is a relatively common siliceous rock. Because flint is hard and produces sharp fractures when broken, it was first favored by primitive people in the Stone Age and used to strike and make stone tools. The striking of flint and iron tools will produce sparks, so it was also used as a fire-making tool by ancient people. In ancient China, a small piece of flint and a steel “fire sickle” were often struck to make fire, so flint is also called flint. The modern grinding industry utilizes its hard and sharp edges as grinding materials.

2.1.7 Silica is the general name for vein quartz, quartzite, and quartz sandstone. The main component is also SiO2. Silica has a wide range of uses. When used in the grinding industry, it can be used to make grinding stones, oil stones, and sandpaper. It can also be used to polish glass, Surface of metal products, sawing and grinding stones, polishing jewelry, etc.

2.1.8 Feldspar is the general name for feldspar minerals. There are many types, such as albite, anorthite, barium feldspar, barium adolite, microcline feldspar, orthoclase, feldspar, etc. The main component is feldspar. Silicon oxide, aluminum oxide, K2O, sodium oxide, calcium oxide, etc. When used in the grinding industry, it is often used as a bond component in the production of bonded abrasive tools, such as grinding wheels.

2.1.9 Chalk is calcium carbonate and has a wide range of uses. It is used in the grinding industry as a raw material for tooth powder, toothpaste and other cosmetics.

2.2 Artificial abrasive media. It is an abrasive material that does not exist in nature and is entirely artificially produced. The main types are:

2.2.1 Sintered abrasives. Mainly divided into corundum abrasive media, silicon carbide abrasive media and CBN (cubic boron nitride) abrasive media, the varieties are divided into:

Brown corundum abrasive media. The main component is Al2O3, which has medium hardness, high toughness, sharp particles, relatively low price, and is suitable for processing metals with high tensile strength.

White corundum abrasive media. Its hardness is slightly higher than brown corundum, but its toughness is poor. It is easy to cut into the workpiece during finishing. It has good self-sharpening, low heat generation, strong finishing ability and high efficiency. Chrome corundum abrasive media is its derivative.

Single crystal corundum abrasive media. Its particles are composed of a single crystal and have good multi-edge cutting edges, high hardness and toughness, strong grinding ability, and low grinding heat. The disadvantage is that the production cost is high and the output is low, so the price is relatively high.

Silicon carbide abrasive media. Divided into black silicon carbide abrasives, green silicon carbide abrasives, cubic silicon carbide abrasives, and cerium silicon carbide abrasives. The main component is SiC, which has high hardness, high brittleness, sharp abrasive grains, good thermal conductivity, and strong wear resistance. It is more suitable for processing hard and brittle metal and non-metallic products. At present, the finishing and cutting of most NdFeB magnetic materials is widely used.

CBN (cubic boron nitride) abrasive media. It is a synthetic super-hard material, its hardness is second only to diamond, and it is an excellent grinding material. Compared with traditional grinding materials, CBN abrasives have excellent grinding performance, especially when grinding cemented carbide, and are more efficient. CBN abrasive media are known as one of the greatest technological advances in the history of the abrasives industry due to their high strength, high wear resistance, excellent hardness close to diamond, and excellent thermal stability. The wear resistance and hardness are more than four times that of traditional abrasives, and its unique chemical properties also make it particularly suitable for grinding ferrous metal materials.

The thermal integrity of CBN abrasive media and their ability to maintain a sharp cutting edge when machining ferrous materials makes them the product of choice for advanced grinding systems. When grinding ferrous metals, they do not react with each other; when grinding steel alloys, they are not easily oxidized. This makes CBN abrasive media the first choice for high-performance grinding wheels for grinding different materials such as cast iron and hard steel.

CBN abrasive media can withstand high temperatures of 1300℃~1400℃, are chemically inert to iron group elements, have good thermal conductivity, have high removal rates when grinding steel, have large grinding ratios, and have long tool life. They are ideal for grinding hardened steel, The best abrasive for metals with high hardness and toughness such as high-speed steel, high-strength steel, stainless steel and heat-resistant alloys. In addition, CBN abrasive tools are also suitable for ultra-high-speed grinding, and metal-based CBN abrasive tools will not break even if the linear speed exceeds 250m/s.

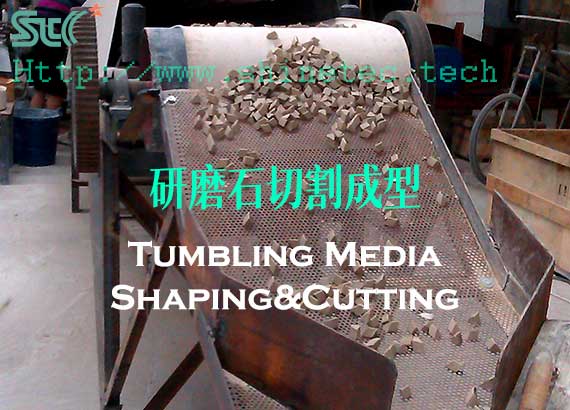

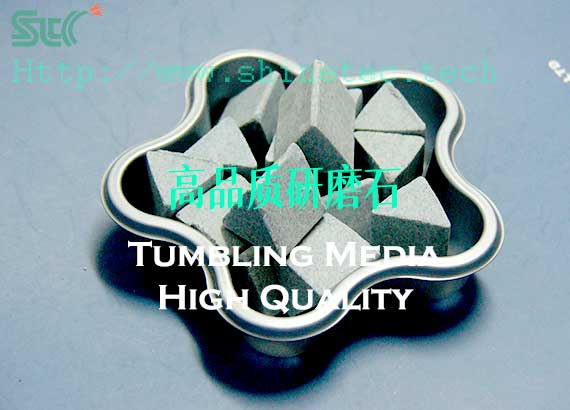

2.2.2 Preformed finishing media.

There are two types of such finishing media: One is sintered ceramic media; also known as ceramic deburring or polishing media. Corundum sand or silicon carbide powder, quartz powder, alumina and other materials are melted at a high temperature of more than 1,000 degrees and sintered into a finishing media with very high hardness. The other is abrasives media bonded with resin, called resin media, polyester media or plastic media. This type of abrasives media can be made into triangular, spherical, square, conical, cylindrical and other shapes. Each shape of abrasives media has different sizes.

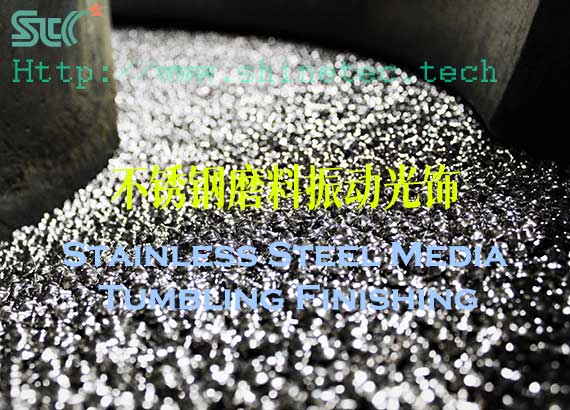

2.2.3 Steel finishing media.

It can be made into hard steel balls, stainless steel balls, ballcone, ufo, needles, pins, angle cut cylinder and other shapes. This type of abrasive media has high strength and is not easily broken. It is mainly used for polishing surface brightness.

2.2.4 Bio-degradable finishing media.

Commonly used ones include corn cobs, walnut shells, sawdust, shredded felt, shredded leather, etc. It is mainly used in the tumble polishing process. It is used for the final polishing and drying of parts that have been treated with light finishes, and can achieve an effect close to mirror polishing.