Deburring, deflashing and polishing technology of laptop middle frame, bezel, chassis of magnesium-aluminum-zinc alloy die-casting parts

How to deburr, deflash, descale, polish magnesium alloy laptop frames of digital product parts?

Among the parts of digital products such as mobile phones, laptops, digital cameras, and tablet computers, the middle frame, bezel, chassis, shell are mostly made of soft metal materials such as aluminum alloy, magnesium alloy, and zinc alloy through die-casting and then CNC precision machining. These metal structural parts often produce burrs, turning lines, and stains during the production process. Therefore, the automated precision finishing and polishing process of the product surface is particularly important. In this case, we will share a magnesium alloy laptop component – the middle frame structure of the automatic high-efficiency deburring, descaling, polishing and brightening process technology and method. This finishing and polishing process solution is also suitable for the deburring, flash removal, burnishing of other soft metal machined parts such as aluminum alloy, zinc alloy, and copper alloy.

- jerrylu

- 2024-06-03

- 0 Comments

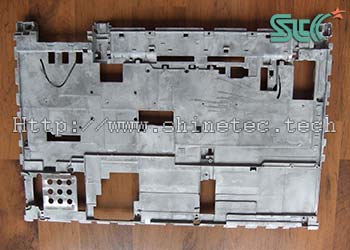

1. The magnesium alloy laptop middle frame before polishing

Materials:

magnesium alloy

Appearance:

burrs and oxide scale on surface

Shape:

ractangular

Size:

350*230 MM

Pre-polishing process:

CNC machining

Post-polishing process:

assembly

2. Finishing and polishing requirements

- deburring, descaling

- smooth surface, no burrs, oxide scale,stain.

3. Details of polishing process for magnesium alloy laptop middle frame:

| Process steps | (1) deburring,descaling of rough finishing | (2) brightening of fine polishing | (3) vibratory drying |

|---|---|---|---|

| Machinery and equipment | rectangular tub finishing machine | rectangular tub finishing machine | vibratory dryer |

| Speed | highest | highest | highest |

| Tumbling media | tetrahedron polyester media | spherical porcelain media | corn cob drying media |

| Abrasive media to workpiece | 4:1 | 6:1 | 8:1 |

| Chemical compound | finishing compound | polishing compound | no |

| Water | appropriate amount, liquid level does not exceed abrasive media | appropriate amount, liquid level does not exceed abrasive media | no |

| Polishing time | 60 minutes | 30 minutes | 15 minutes |

| Remark | parts separated and picked up automatically, rinsed with water | parts separated and picked up automatically, rinsed with water | parts separated and picked up automatically, rinsed with water |

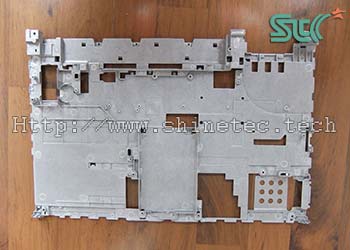

4. Deburring, deflashing, polishing effect of the magnesium alloy laptop middle frame

5. Additional instructions

-

Aluminum-magnesium alloy frame, bezel, chassis is an important part of electronic digital products. Due to its light and soft material, and the complex and special-shaped parts such as holes, gaps, and corners on the surface, the dimensional accuracy is high. Therefore, the cutting force for removing burrs, flash and oxide scale should not be too heavy, and the complicated body of parts should be fully polished. Therefore, the polishing machine adopts rectangular tub finisher, and small-sized tetrahedron-shaped plastic media is used for rough finishing, mixed with large-sized cone-shaped polyester media, the sharp angle of the plastic media can reach deep into the grooves and corners to remove burrs and oxide layers.

Fine polishing uses precision ceramic polishing media without cutting force, spherical porcelain polishing media, which has a high density and has a polishing and brightening effect, which can further reduce the surface roughness. - In order to improve the anti-rust performance of the product after water treatment, use a vibratory drying machine with corn cob polishing media to absorb moisture and dry the inner and outer surfaces.

6. Final summary

- In this case study, we demonstrated the process of automated deburring, descaling, deflashing, polishing and brightening of the surface of a precision magnesium alloy frame component for a laptop computer.

-

If you need professional technical support for deburring, deflashing, descaling and polishing of electronic products such as mobile phones, tablets, digital cameras or other magnesium-aluminum alloy precision machining parts, you can refer to the above cases:

Polishing process for digital product parts

Deburring of mobile phone middle frame

Can the middle frame be polished?

Finishing and polishing of bezel, chassis

Polishing skills of magnesium alloy

Surface treatment method of magnesium alloy

Precautions for polishing magnesium alloy

Pretreatment of magnesium alloy electroplating

Deburring of aluminum alloy

Polishing process of aluminum alloy

Polishing method of aluminum alloy

What is the best way to deburr aluminum parts

Deburring process of metal surface

Method of metal deburring

Finishing solution of metal burrs and flashes